-

17

2025/07

Chunhua Crane Provides You with the Best Crane Customization Solution

In order to offer the most suitable crane design solution for you, It will be great helpful if you can offer us the following information to us: 1.Lifting capacity. 2.Span length.(rail center to rail center) 3.Lifting height.(hook center to ground) 4.Have you installed the rails?Do you need us to supply the rails?How long is it? 5.Power supply:Voltage. 6.Working condition:What kind of material to lift?Temperature? 7.It would be much better if it is possible for you to offer the drawing photo of your wor...

-

07

2025/07

How long is the crane warranty?

Our lifting equipment has a 2-year warranty. If you have any problems with the equipment during this period, please feel free to contact us. We will provide you with a maintenance plan for the lifting equipment.

-

07

2025/07

What is the delivery time of lifting equipment?

The estimated delivery time for crane equipment and crane components of different capacities is different, generally about 15 to 40 days. You can consult our company for specific lifting equipment and accessory models to communicate the delivery time.

-

30

2025/06

What mode of transportation does Chunhua Hoisting Machinery use?

We recommend air transport or LCL for small quantities of lifting equipment, and container or bulk carrier for large quantities of lifting equipment.

-

30

2025/06

Does Chunhua Crane accept OEM business?

Sure, we do many OEM productions for some famous crane brand and customers around the world.

-

30

2025/06

Are you Manufacturer or Trading Company?

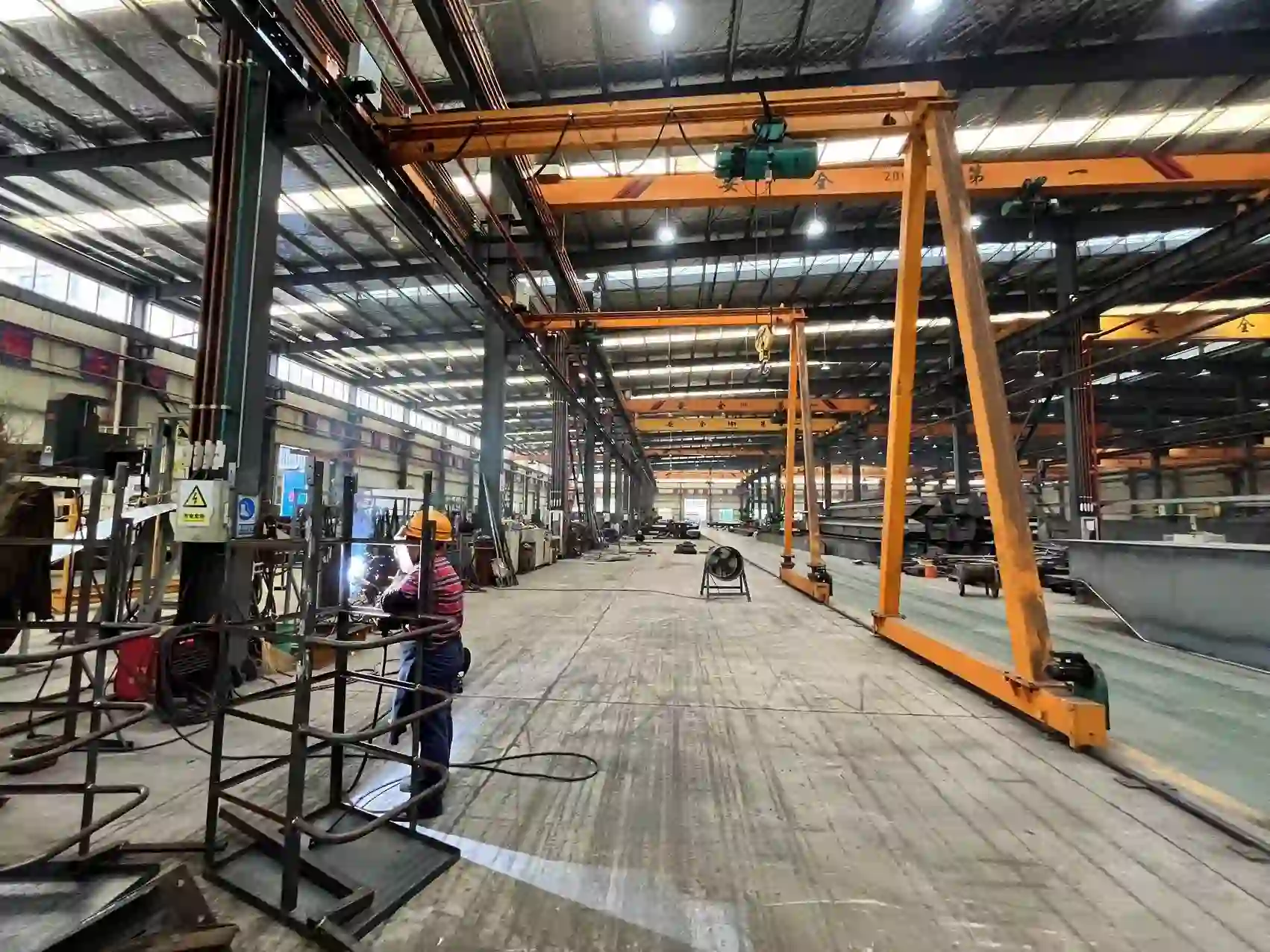

We are an crane equipment manufacturer. We have our factory,R&D team,and marketing department.

-

12

2024/07

Why did we hobbed gears processed by gear hobbing machines on cranes?

Reliability: Gear hobbed gears provide high precision and stable transmission, enhancing the operational reliability of the crane. Durability: High-quality gears reduce wear and extend the crane's service life. Efficiency: Optimized transmission systems improve the crane's operational efficiency and energy utilization. Safety: Precise gear transmission helps enhance the crane's safety performance, reducing the risk of accidents. Adaptability: Hobbed gears can be customized according to crane design requ...

-

11

2024/07

How to install an overhead crane?

Confirm the installation site and infrastructureInstall tracks and supporting structuresAssemble the bridge and trolleyInstall the electrical system and controllersConduct debugging and testing to ensure normal crane operation

-

09

2024/07

What is a Semi-Gantry Crane?

A semi-gantry crane is a type of bridge crane where one end beam runs on an elevated track while the other end beam runs on a ground track. It is typically used for material handling both indoors and outdoors.

-

03

2024/07

How is the steel required for crane production processed?

Material Selection and Procurement: Select suitable steel for crane applications, such as high-strength low-alloy steel (HSLA), carbon steel, or alloy steel. Cutting: Use cutting machines (such as plasma cutters, laser cutters, or flame cutters) to cut the steel plate into the desired size and shape. Forming: Shape the steel plate into specific forms, such as beams or support structures, through bending, rolling, or stamping processes. Welding: Use various welding techniques (such as gas-shielded welding, subm...

-

02

2024/07

What are the steps for producing the main beam of the crane?

Material Preparation: Select appropriate steel, usually high-strength low-alloy steel, and cut and prepare it according to design requirements. Welding Assembly: Weld the steel plates and steel beams into the basic framework of the main beam. This process requires ensuring the quality of the welds to guarantee the strength and stability of the main beam. Correction and Straightening: After welding, the main beam may deform, so correction and straightening are needed to ensure the straightness and geometric dimensions...

-

01

2024/07

Does installing a gantry crane require a foundation?

Whether a foundation is required depends on the specific model of the gantry crane and the operating environment. Here are some common scenarios: Lightweight portable gantry cranes: Usually do not require a foundation and can be used directly on a flat, solid surface. Medium and heavy-duty gantry cranes: Typically require a foundation to ensure stability and safety. The foundation prevents the gantry crane from tilting or moving during operation. Indoor gantry cranes: If the floor is sufficiently strong and level, an add...