Introduction to Hefei Chunhua KBK Lightweight Modular Crane System

Company Credentials

- National Quality Supervision and Inspection Certification: Holds crane “Manufacturing License” and “Installation, Transformation, and Maintenance License.”

- International Standard Certification: ISO9001 Quality Management System ensures product reliability.

- 27 years of industry experience: Focused on crane equipment research and development, with mature technology.

Product Definition

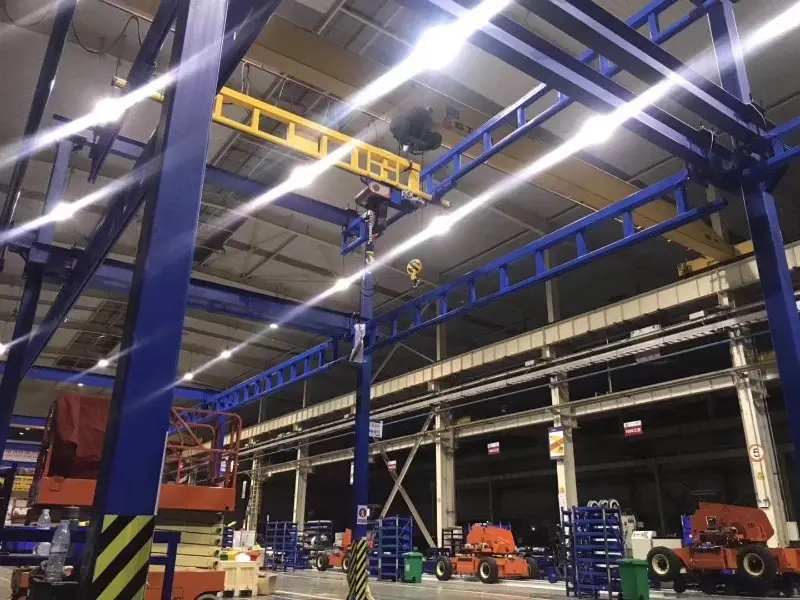

Single Beam KBK Crane (KBK-I)

Consists of a cold-rolled KBK-specific track as the main beam, paired with electric/manual chain hoists, rated load 80 kg – 1,250 kg.

Double Beam KBK Crane (KBK-II)

Uses two parallel KBK tracks as the main beams, with a more stable bridge structure. Rated load 1,000 kg – 3,200 kg, can integrate larger power walking drives.

Core Advantages of KBK Crane System

- Modular Design: Standardized components (track, lifting points, walking mechanism) for quick assembly, supporting system expansion and reorganization.

- Flexible Layout: Tracks can be arranged in straight, curved, or branching lines, adapting to complex workshop layouts.

- Lightweight Structure: Aluminum alloy tracks reduce the factory’s bearing requirements, cutting installation costs by over 30%.

- Precise Positioning: Manual/electric push/pull force ≤ 1 kg per 100 kg load, achieving millimeter-level fine adjustment (±1 mm).

- Low-Cost Operation and Maintenance: Maintenance-free design, easy module replacement, with minimal downtime.

Single Beam KBK Crane vs. Double Beam KBK Crane

| Dimensions | Single Beam KBK Crane | Double Beam KBK Crane |

| Structure | Single main beam + electric hoist | Double main beams + trolley lifting mechanism |

| Rated Load | 0.125-2 tons (economical light load option) | 1-5 tons (heavy-duty, high-efficiency option) |

| Applicable Scenarios | Small parts assembly lines, machine tool workstation delivery, maintenance areas | Frequent lifting production lines, warehouse logistics, medium-sized equipment installation |

| Space Adaptability | Low headroom requirement, compact design | Requires more vertical space, stronger span support |

| Positioning Accuracy | ★★★★☆ (small hoist swing) | ★★★★★ (double beam structure is more stable with excellent swing suppression) |

| Cost Composition | 30% lower investment cost, cost-effective choice | Higher initial investment, but better long-term cost efficiency for high-frequency use |

| Typical Application Cases | Automotive parts production line, electronics workshop material handling | Mold workshop, packaging center, metal processing area |

Industry Application Solutions

Intelligent Manufacturing Sector

- Single Beam: Precision instrument assembly lines (under 1 ton material airborne transportation)

- Double Beam: Stamping machine mold replacement (3-ton level quick positioning)

Warehouse Logistics Center

- Single Beam: Light goods transfer in picking areas

- Double Beam: Palletized cargo loading and unloading (with vacuum suction cups/clamps)

New Energy Production Line

- Double Beam: Battery module lifting (anti-sway control and precise docking)

Selection Recommendations:

Choose Single Beam: If the budget is limited, load ≤ 2 tons, and space is compact.

Choose Double Beam: For high-frequency lifting, load ≥ 3 tons, and high-precision requirements.

With 27 years of industry experience, Chunhua Cranes has provided over 10,000 sets of KBK systems for highways, railways, industrial buildings, and multi-story garages. We hope this information helps you quickly find the most suitable solution for your production line.